3D Printers are slowly emerging into the consumer market. The technology is still in the infancy stage, and the manufacturers are competing to conquer the 3D printer market. Ideally, a 3D printer can print anything with a given material that ranges from a coffee cup to an entire house.

The price of the 3D printer is coming down day by day, and now cheap 3D printers are available in the consumer market to print hobby models and toys. These cheap 3D printers can be used to print hobby projects, home decorative items, toys, etc.

This is not a review of 3D printers currently on the market. This article is a 3D Printer buying guide that you can refer to. In this 3D printer buying guide, we are listing a few important and critical things you should consider when you select your 3D printer.

We hope this buying guide for 3D printer features and 3d Printer specifications help you to pick the right printer for your needs.

What is a 3D Printer?

Our traditional paper printers are 2D printers that prints in 2 dimensional in X and Y direction. 3D printers are capable of printing in three dimensions in X, Y, and Z direction. These printers can print or model the required objects if you have a right 3D diagram of the model. If you have a 3D image, you can print from toys, spare parts of a Car, Jet Engines and even the parts of the human body.

3D printers are initially build to use in industry to make their product prototypes in a very short time. Eventually, more printer models are built to make body parts for the military, NASA. Now cheap 3D printers are available in the consumer market to print hobby models and toys.

You can print the small prototype of your home that you are planning to build in the future. You can touch, feel and modify by seeing a real model of your future home. If you are a civil engineer, you can extend the capability of this technology to prototype flyovers, bridges, building or even a city.

Related: 7 Best VR Headsets to Experience Virtual Reality on your Smartphone

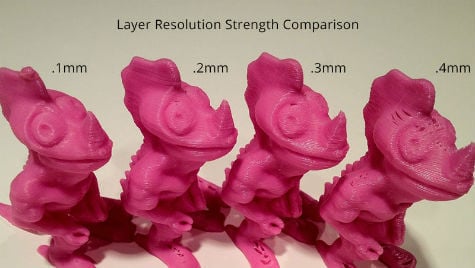

3D Printer Resolution

(Range from 0.02mm to 0.4mm)

We measure the resolution of the 2D printer in pixels that represent the clarity of the picture it paints. In 3D printers, high resolution means good finishing and the ability to reproduce high details of your final model. 3D printer resolution defines the thickness of printing layers measured in microns. That means if you own a lower number resolution printer that can reproduce the great details of the model.

(image courtesy: airwolf3d.com)

A high-resolution printer will be more expensive and slower to print the object. Most of the printers are offering to adjust the resolution based on your requirement. If you don’t care about the cost, go for the top resolution printers. High-end models are the professional models they offer lower micron (high resolution) printing resolution.

3D Printer Technology

There are different types of technology using to print the material to generate a model. This technology determines how the printing process with the filament can be done in 3D Printers.

Fused Deposition Modeling

Most of the commercial 3D printers are working based on this technology. FDM printing is an additive process, where layers are adding on top layer by layer by heating the extruding the plastic.

Stereo Lithography

In this method, the ultraviolet light beam is using to harden the material from a pool of photosensitive liquid instead of printing as layers on top. This method is using for high-quality, precise printing jobs in an industrial environment.

Selective Laser Sintering (SLS)

This approach is using the laser beam for high precision printing instead of ultra-violet. In SLS the printing material is a powder, and a laser beam is using to melt this powder and create the models.

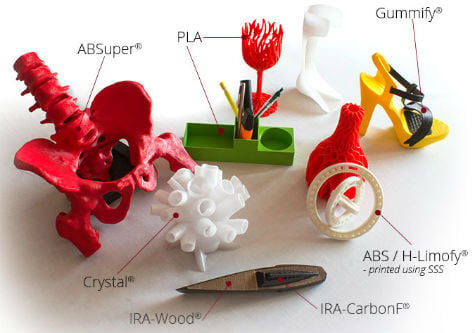

3D Printer Filament Types

3D Printers can support a variety of materials to print based on your model requirement. Most of the printers are supporting only one or two material in one printer. That means if you want to make designs with different materials, you may need to shop around more than one 3D printer to meet your requirement.

PLA 3D Printer Filament.

PLA material is corn Starch-based. This filament is Biodegradable and more versatile that suited for most common printer jobs. This can cool and reach a stable state in very short time, good for quick and fast jobs.

(image courtesy: ira3d.com)

The model gives a glossy look with this material. The downside is that since this material has a low melting point (Extrude at 190°-220°C), not recommended to print high heat applications and joint and fixing parts.

ABS 3D Printer Filament.

Acrylonitrile Butadiene Styrene is a petroleum-based material, and this material is heat resistant, durable and ideal to print the models that need to withstand more wear and tear. This material is suitable to make interlocking parts (LEGOs made with ABS) and also low melting point (Extrude at 230°-260°C) but better than PLA. This takes more time to settle and emits fumes while printing.

PC 3D Printer Filament.

Polycarbonate filament is used in places where you need to handle the high impact.

Carbon Fiber Based 3D Printer Filament.

Carbon Fiber printed models are up to 20 times stiffer and 5 times stronger than similar ABS parts 3D printed using ABS plastic.

3D Printer Hybrid PLA filament is coming with a Wood-Based and Metal based material. The metal based filament used for jet engine parts and other industrial applications.

3D Printer filament selection is based on your job requirement. Please keep in mind that none of the printers are supporting more than one or two filaments at a time. So please make sure you are choosing the right filament printer based on your job.

3D Printer Bed Types

Printer beds are coming with Heated and Non-heated models. The printer bed is the one where your model is going to build up. To fix the model on the based and avoid warping while print, either need to apply some glues or preheat the bed to fix the model on the base at the beginning of the printing process. ABS need a heated bed, and for PLA filament, it is optional. We recommend heated bed 3D printers that will be suitable for PLA, ABS and all other materials as well.

3D Build Volume

(Range from 1 cubic inch to 12 cubic inches)

Build volume is an another important parameter that you need to be select carefully for your-your 3D printer. Build volume is a measure that determines how much big model that can regenerate by the printer.

It is usually measured in cubic mm or inches that specify the three axis movement limit of the printer head. The higher numbers represent the ability to reproduce a reasonable size of models. Printing large volume objects required a considerable amount of time in setup to calibrate your printer.

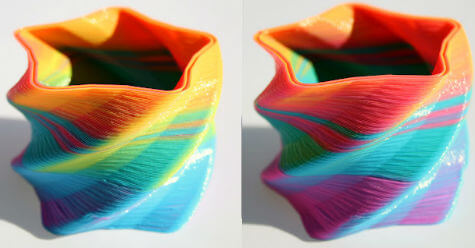

Multicolor Support

(Supports 1-3 colors)

Multicolor printers can print more than one color in a single print job. These multicolor supporting printers equipped with multiple filaments with different colors. You can load these colors individually based on your requirement in each printer heads before you start the job.

(image courtesy: airwolf3d.com)

These printers are expensive since it needs to handle multiple extruder heads for each color at the same time and the machine need to be more sophisticated.

3D Printer Speed

Print speed is an important feature you need to consider while you select your printer. 3D Printer speed is a trade between the speed and resolution of the printer. If you need to print and object with high details, the speed is going to be low.

The printing material and printing technology are the other factors hat determining the print speed. Always go for a high-speed and high-resolution printer based on your spending ability for more flexibility and high performance.

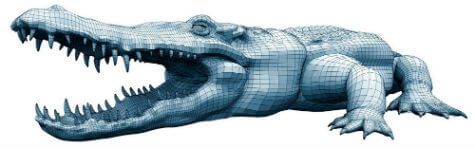

3d Printer Software and Apps

3D Printers need designing software to design and build 3D files. These files are supposed to feed into the printer to create the models. These applications let you visualize the 3D concept and convert the base images to a 3D image.

(image courtesy: sketchup.com)

These software are categorized into three types, CAD Tools (using geometrical shapes to build models), Freeform Modeling Tools (create freeform shapes ) and Sculpting tools (can push, pull, pinch and grab to form your models)

We selected list of 3D Modeling tools based on our reader’s experience and the best reviews and customer reports. The final selection of your printer should be based on your need and market research.

3D Printer other Features Need to Consider

There are some other factors that need to consider while you buy a 3D printer but not necessary like other key features. I would say these are the fancy features but better to have them if you can afford.

3D Printer Camera

In a 3D printer, the camera is using for two purposes. The camera gives you an ability to check your print progress by watching them from a remote location either using your phone or computer. The second purpose is to scan the object that needs to be print. This camera/s based printers are more expensive, and it can scan your basic model and convert into an image file to print itself and make copies.

3D Printer User / LCD Interface

LCD interface is used for the user to interact with the printer and to send the instructions and get the status of the print job. But usually, most of the printers are coming with built in app that is capable of communicating with your PC directly and see the status on your PC monitor.

Cloud Connectivity for 3D Printer

Cloud-based 3D printers are advanced printers that can keep the 3D files on the cloud. These 3D files can access from cloud online on demand. With cloud connection, you don’t need any separate memory or local hard disk to save 3D image files. The files can be pushed directly from cloud to the printer.

Get 3D Model to Print

When you buy your first 3D printer, the printer is coming with a bunch of free 3D Models. If you want more image files, you can find out a bunch of sites those offering free 3D models to try on your 3D printer.

3D printers are expensive, and you have to do your market research before you order first 3D printer. You should have some idea on what kind of 3D printer you are looking for and the purpose of your printer before you spend from your pocket.

We have consider all the points while buying 3D printer.

Nice blog! Mostly, users are familiar with 2D printer only as they are using Fuji xerox1400 machine at home. They have heard a lot about 3D printer but have no experience. While going through this blog I came to know about many new terms and guideline that we need to consider while buying such machines. Thanks for sharing such a rich content.